The Brief – This block of 4 units near Manly Wharf had extensive corroded brick wall ties and arch window lintels. Helitec were called to reinstate the structural integrity and appearance of the building. We discovered that four particular areas needed repairs to return this unit block to its former glory.

Corroded Brick Wall Ties – Helitec undertook an extensive inspection of the external brick walls. After the location of the galvanised steel wall ties and using our borescope camera the inspection discovered the galvanised cavity brick wall ties had suffered extensive corrosion and there was insufficient density of ties (i.e. ties/m2). We also removed a sample of bricks and concluded there was little functionality of the remaining ties.

- Insertion of 650 no. Helifix Stainless Steel Resities to the external cavity brickwork.

- Drill holes through the outer masonry leaf and into the backup substrate to insert 8mm x 205mm wall ties.

- Insert Epoxyplus resin into the backup substrate by a tube until the hole is completely filled.

- Push the Resitie through the hole in the outer masonry leaf and wind the tie into the backup substrate.

- Place Epoxyplus resin over the exposed Resitie in the outer leaf. Protect the area around the hole by use of masking tape. Inject resin until the hole is filled.

- Allow the resin to cure and make good.

Corroded Window Arch Bars and Damaged Brickwork – The curved steel arch bars above the windows and exterior doors were badly corroded and had expanded which lifted and damaged the bricks above and around the openings. Helitec manufactured bespoke stainless steel lintels to suit the curve of each window. The openings were propped before removal of damaged bricks and the window arches were successfully rebuilt with matching bricks.

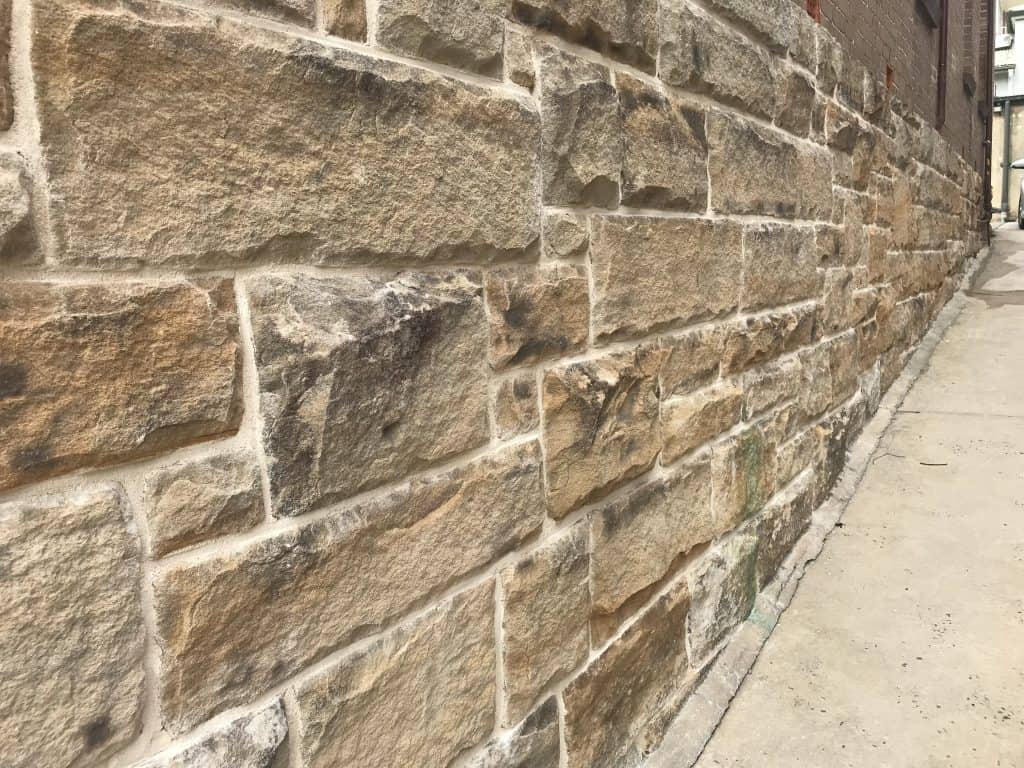

Degraded mortar jointing of stone footing walls – The mortar joints between the stone blocks at the base of the walls had suffered sever environmental weathering from the winds of the nearby Manly Bay. Large parts of the mortar joints were missing. The mortar was unsightly and crumbly.

- Supply pre-blended heritage lime mortar with a matched colour.

- Rake out damaged and degraded mortar from the sandstone blocks to a depth wide enough where the new mortar can hold.

- Clean the hole of any dust and dirt and spray out the joints with water.

- Carefully apply new mortar into the gaps using a finger trowel making sure no mortar is left on the sandstone. The new mortar is shaped to sit just lower than the face of the wall.

- Clean and make good all sandstone from excel mortar.

- Spray the joints with water from time to time to delay the drying out of the new mortar.

Decaying window sills and window frame paint – Due to difficult access the painting of the windows had not completed for some time. This caused the widows frame paint to become flaky with some rotting of the window sills. It was decided by the building owners to have the paint restored whilst the Helitec supplied scaffolding was in place.